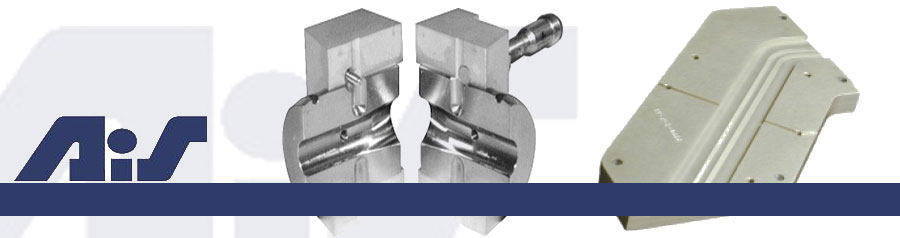

Now there is a faster, easier, and more economical way to install O-rings onto components and assemblies in lower  volume applications. O-rings are manually loaded into a magazine and then automatically placed onto a two-stage installation mandrel. The operator places the component into the mandrel and, with a light push, installs the O-ring on the part.

volume applications. O-rings are manually loaded into a magazine and then automatically placed onto a two-stage installation mandrel. The operator places the component into the mandrel and, with a light push, installs the O-ring on the part.

- Compact, Lightweight, Benchtop Mounted Machine

- Increases Production Rate – cycles up to 45 times per minute

- Eliminates rolling or twisting of O-rings

- Reduces operator fatigue

- Accommodates O-rings ranging from .150” to 1.00”*

*Dependent upon the ratio of cross section to outside diameter and the stretch requirement. - Dimensions: 18.25” L x 11” W x 18.5” H (Dimensions may

vary depending on the application.) - Requires 90 psi air supply. No electric power needed.

- Quick-change installation heads and magazines for multiple applications.