Automated Industrial Systems Inc. (AIS) was founded in 1977 as a custom machine builder. Shortly after its founding, AIS saw the need for a faster, more reliable method of installing external O-rings onto a variety of parts.

Our first ASP O-ring machines were manufactured in 1978, and since that time AIS has continued to develop the technology needed to install O-rings in a production environment. In the last two decades, the ASP series of O-ring installation machines have become the accepted method of O-ring installation at most major manufacturers. Over 1,200 machines have been produced.

The ASP machines are available in a variety of models and sizes for many applications. Some of the major benefits of the machine are:

Speed - A single operator can normally achieve rates of over 50 installations per minute. This has proven to be several times faster than the manual methods traditionally used in many plants.

Flexibility - A single machine can be provided with extra tooling to run a variety of parts and O-rings. Tooling change is simple and can be accomplished in minutes.

Reliability - AIS's O-ring installation machines have proven to be low maintenance, highly reliable production equipment. The majority of machines manufactured twenty years ago are still in production. An extensive user list is available from AIS.

Quality - Because the O-ring is slid onto the part and is never twisted or rolled, no damage to the O-ring can occur.

Ergonomic - The machine is designed to use a minimum of operator force and movement.

Automation - With the addition of standard automation modules, the ASP machines can be easily integrated into existing production lines or onto completely automatic assembly machines. We have a long history of successfully working with many major assembly machine manufacturers.

Up to 6 times faster than hand assembly...

...with the ASP-1 O-Ring Installation Machine

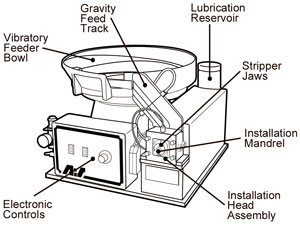

The ASP series of O-ring and seal installation machines are semi-automatic systems which install external O-rings and seals onto components. The machines utilize a vibratory feeder bowl which provides a steady flow of O-rings or seals to the installation head and mandrel. By simply pushing the mandrel, the machine automatically installs the O-ring or seal onto the component. The machine then cycles a new seal into position for the next component.

The ASP machine can install O-rings, Teflon rings, quad rings, cup seals, lip seals, and metal snap rings onto a variety of components. The machines are capable of installing seals up to 3" in diameter and up to a rate of 55 parts per minute.

AIS's standard ASP O-ring and seal installation machines are comprised of two basic elements; a chassis and installation head.

Chassis - The chassis of the ASP consists of a tooled vibratory feeder bowl, electronic control box, lubrication  system, and all mechanisms required to operate the machine. The components are mounted on a compact base plate.

system, and all mechanisms required to operate the machine. The components are mounted on a compact base plate.

The lubrication system is incorporated into the ASP to ensure that the seal slides, not rolls, off the mandrel onto the part. The standard lubrication system can accommodate a variety of lubricants with a viscosity of between 50 and 350 centistokes. Lubricants thicker than this must be evaluated separately. Some standard lubricants include alcohol, brake fluid, mineral oil, motor oil, PAG oil, silicone oil, transmission fluid, and vegetable oil.

It is important to note that the lubrication system is designed to prevent the seal from rolling during the installation process. It is not meant to thoroughly coat the seal.

Installation Head - The installation head is the portion of the machine that  installs the O-ring or seal onto the part. It is custom for each application. By purchasing additional head assemblies, different size O-rings can be installed using the same chassis.

installs the O-ring or seal onto the part. It is custom for each application. By purchasing additional head assemblies, different size O-rings can be installed using the same chassis.

The installation head consists of a feed track, internal plates, mandrel, and a set of stripper jaws. The feed track carries the O-rings from the feeder bowl into the head. Inside the head, the internal plates position an O-ring for installation. The mandrel expands the O-ring and positions the part at the correct depth for O-ring installation. The stripper jaws strip the expanded O-ring off the mandrel and onto the part.

Tooling Changes

The installation head is located on dowel pins and is easily removed by two machine screws. Tooling change for another size O-ring or seal can be accomplished in a matter of minutes.

Principle of Operation

The O-ring or seal is automatically oriented in the vibratory feeder bowl into a vertical ("rolling tire") position. It is then moved into the installation head via the gravity feed track. Inside the head the internal plates position the O-ring for installation by the mandrel.

The operator places the part into the counterbore of the mandrel and pushes inward. The stripper jaws then strip the O-ring off the mandrel onto the part. At the same time, the tail of the mandrel is pushed through the I.D. of the next O-ring or seal that is to be installed.

The mandrel position is sensed electronically and pulled through the I.D. of the O-ring. The mandrel movement is then reversed and the O-ring or seal is brought to the front of the stripper jaws, ready for the next installation.

The ASP in the home position with the O-ring ready for installation.

The ASP in the home position with the O-ring ready for installation.

The operator places the part in the counterbore of the mandrel and pushes in, stripping the O-ring onto the part and causing the tail of the mandrel to pass through the I.D. of the next O-ring.

The operator places the part in the counterbore of the mandrel and pushes in, stripping the O-ring onto the part and causing the tail of the mandrel to pass through the I.D. of the next O-ring.

The mandrel position is sensed electronically and pulled through the I.D. of the O-ring, expanding it to the correct dimension for installation.

The mandrel position is sensed electronically and pulled through the I.D. of the O-ring, expanding it to the correct dimension for installation.

The mandrel movement is then reversed and the O-ring is presented to the operator and the cycle is ready to be repeated.

The mandrel movement is then reversed and the O-ring is presented to the operator and the cycle is ready to be repeated.

Configurations

Automated Industrial Systems' seal installation machines are available in a variety of configurations. All models can be ordered as either right-hand (counter-clockwise feeding) or left-hand (clockwise feeding) systems. The combination of a right-hand machine and a left-hand version is a practical, ergonomic solution for an application requiring two seals on the same part. Go back to External O-Ring Installation Machine

Automated Industrial Systems' seal installation machines are available in a variety of configurations. All models can be ordered as either right-hand (counter-clockwise feeding) or left-hand (clockwise feeding) systems. The combination of a right-hand machine and a left-hand version is a practical, ergonomic solution for an application requiring two seals on the same part. Go back to External O-Ring Installation Machine