Using the expertise gained from over 20 years of manufacturing external O-ring installation equipment, Automated  Industrial Systems (AIS)

Industrial Systems (AIS)

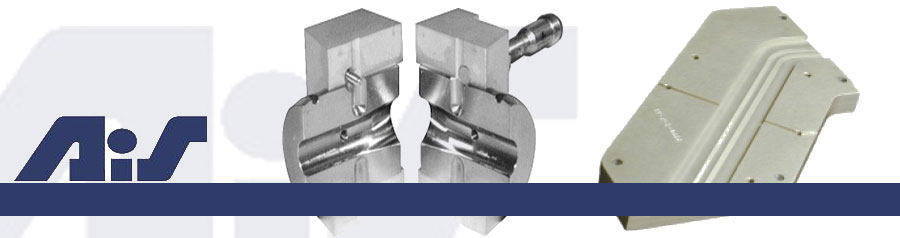

Part with two internal O-rings installed. manufactured its first internal seal installation machine in 1998.

The internal seal installation machine can install an O-ring or seal into a recessed groove or push the seal into a cylinder. The operator simply places the part into a holding fixture, actuates the machine, and the seal is automatically installed into the internal groove.

o-ring assembly machineO-Rings are fed and oriented via a vibratory feeder bowl into a gravity track. The O-ring is positioned on a collet-like collapsing mandrel mounted on a rotary actuator. The mandrel then pushes the seal through a funnel which compresses the O-ring and positions it at the proper depth. The funnel also has ports to lubricate the inside the funnel so the O-ring

o-ring assembly machineO-Rings are fed and oriented via a vibratory feeder bowl into a gravity track. The O-ring is positioned on a collet-like collapsing mandrel mounted on a rotary actuator. The mandrel then pushes the seal through a funnel which compresses the O-ring and positions it at the proper depth. The funnel also has ports to lubricate the inside the funnel so the O-ring  slides rather than rolls inside the funnel. The mandrel pushes the O-ring beyond the end of the funnel so it snaps into the groove. The mandrel then retracts and the cycle starts again.

slides rather than rolls inside the funnel. The mandrel pushes the O-ring beyond the end of the funnel so it snaps into the groove. The mandrel then retracts and the cycle starts again.

Rates of 25 to 30 parts per minute are easily achieved. The machine can be tooled to accommodate a variety of different sized o-rings or seals, and can be integrated into automatic assembly systems. Some of the major benefits of the Internal O-Ring Installation Machine are:

Speed - A single operator can normally achieve rates of approximately 25 installations per minute. This has proven to be several times faster than the manual methods traditionally used in many plants.

Flexibility - A single machine can be provided with extra tooling to run a variety of parts and O-rings. Tooling change is simple and can be accomplished in minutes.

Reliability - AIS's O-ring installation machines have proven to be low maintenance, highly reliable production equipment. The majority of machines manufactured twenty years ago are still in production. An extensive user list is available from AIS.

Quality - Because the O-ring is slid into the part and is never twisted or rolled, no damage to the O-ring can occur.

Ergonomic - The machine is designed to use a minimum of operator force and movement.

Automation - The Internal O-Ring Installation Machine can be easily integrated into existing production lines or onto completely automatic assembly machines. We have a long history of successfully working with many major assembly machine manufacturers.